Department of Smart Manufacturing Engineering

The Department of Mechanical Engineering was established in 1969 as one of the founding departments of the school and was renamed the Department of Smart Manufacturing Engineering in 2025. Over the past 50 years, the department has cultivated numerous outstanding professionals in the field of mechanical engineering. Its greatest strengths lie in its well-established faculty and comprehensive facilities. The department houses a dedicated Smart Manufacturing Center, one internship factory, and eleven professional internship and laboratory rooms, providing practical training and research environments across various areas of mechanical engineering. The faculty includes 10 professional instructors, 9 of whom hold doctoral degrees. In recent years, the department was awarded nearly NT$21 million in funding from the Ministry of Education’s Technical and Vocational Education Reengineering Project, enabling the acquisition of modern and well-equipped teaching facilities.

The Department of Smart Manufacturing Engineering is dedicated to developing future leaders in smart manufacturing, equipped with a rich blend of skills in “Mechanical Design and Manufacturing,” “Smart Mechatronics,” and “AI Technology Application.” Our program’s highlights include:

- Integrating Mechanical Design and Manufacturing: We equip students with essential mechanical theories and hands-on experience in CAD/CAM applications. Our curriculum is designed to enhance students’ practical design skills while providing extensive training in precision manufacturing technologies.

- Advancing Smart Mechatronics Technologies: Our program fosters strong digital logic and computing skills, offering deep insights into mechatronics integration, automatic control, and sensing technologies. Students develop proficiency in artificial intelligence applications, preparing them to innovate in smart manufacturing systems.

- Enhancing AI Technology Application Capabilities: We empower students with advanced AI skills, crucial for the modern smart manufacturing landscape. The curriculum includes comprehensive training in digital network security management to safeguard manufacturing systems against emerging threats.

- Cultivating Interdisciplinary Practical Techniques: By merging cross-disciplinary knowledge with hands-on skills, our students gain practical experience through internships in smart factories and specialized projects in smart manufacturing, ensuring they are industry-ready upon graduation.

Curriculum Planning

Educational Objectives

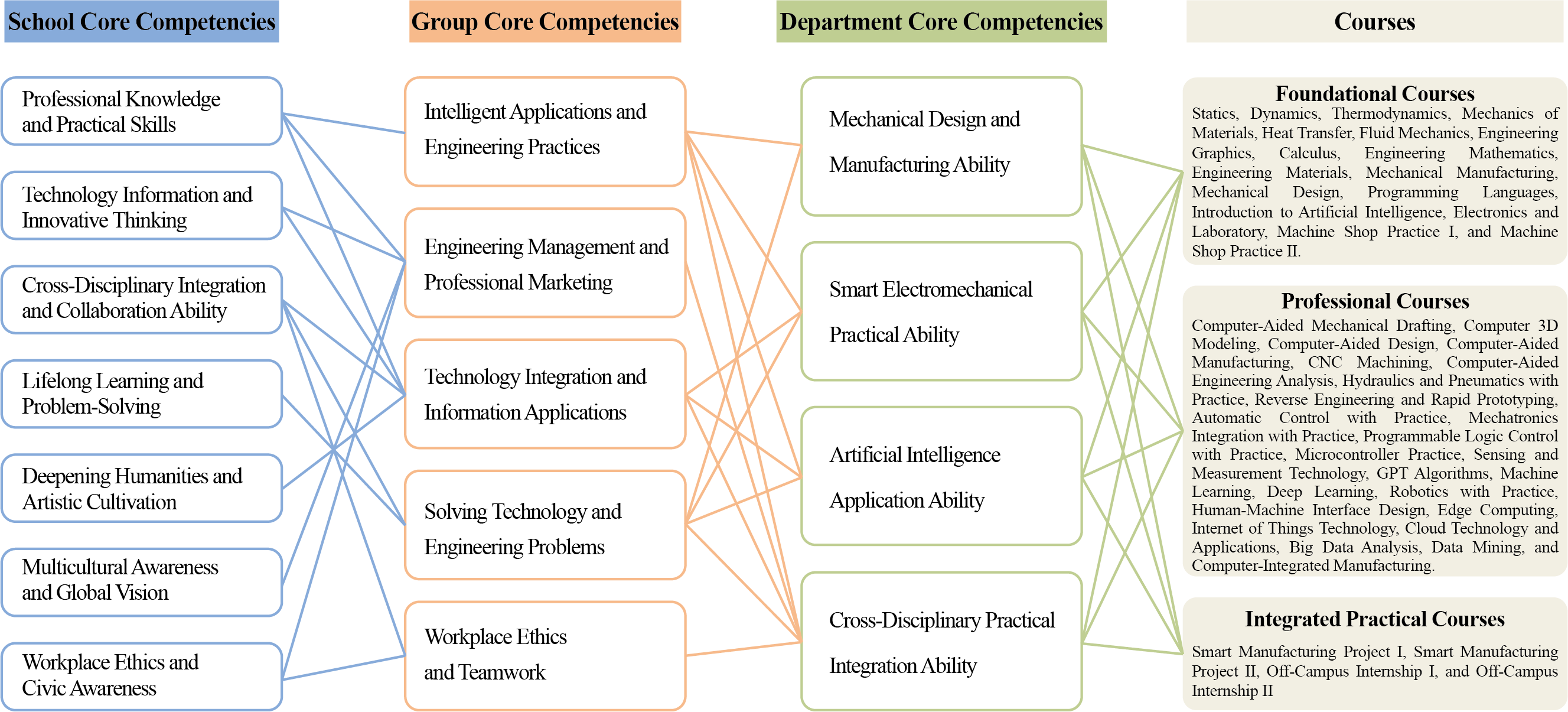

The Department of Smart Manufacturing Engineering focuses on cultivating professionals with cross-disciplinary practical skills in mechanical design and manufacturing, smart electromechanics, and AI technology applications. In alignment with the educational objectives, the department has established the following core competencies:

Curriculum Structure and Development

In addition to aligning with the school and college core competencies by offering common required courses and college-designated professional required courses, the department has designed its curriculum to support its educational objectives. Based on the educational goals and core competencies, the curriculum is structured into three main sections: Foundational Rooting Courses, Specialized Feature Courses, and Integrated Practical Courses, which are explained as follows:

1. Fundamental Core Courses:

The curriculum focuses on training students in fundamental competencies relevant to the field. Key courses include Statics, Dynamics, Thermodynamics, Mechanics of Materials, Heat Transfer, Fluid Mechanics, Engineering Graphics, Calculus, Engineering Mathematics, Engineering Materials, Mechanical Manufacturing, Mechanical Design, Programming Languages, Introduction to Artificial Intelligence, Electronics and Laboratory, Machine Shop Practice I, and Machine Shop Practice II.

2. Professional Courses:

The curriculum emphasizes the development of professional technical skills in smart manufacturing. Key courses include Computer-Aided Mechanical Drafting, Computer 3D Modeling, Computer-Aided Design, Computer-Aided Manufacturing, CNC Machine Tools and Practice, Computer-Aided Engineering Analysis, Hydraulics and Pneumatics with Practice, Reverse Engineering and Rapid Prototyping, Automatic Control with Practice, Mechatronics Integration with Practice, Programmable Logic Control with Practice, Microcontroller Practice, Sensing and Measurement Technology, GPT Algorithms, Machine Learning, Deep Learning, Robotics with Practice, Human-Machine Interface Design, Edge Computing, Internet of Things Technology, Cloud Technology and Applications, Big Data Analysis, Data Mining, and Computer-Integrated Manufacturing.

3. Integrated Practical Courses:

To enhance cross-disciplinary integration and practical implementation skills, key courses include Smart Manufacturing Project I, Smart Manufacturing Project II, Off-Campus Internship I, and Off-Campus Internship II.

Contact

Phone: 886-02- 2909-7811 Ext 2042

Email: lit00661@mail.lit.edu.tw